Conveyor Belts for Wood and Metal Processing

We produce BestBelt feed belts for wide belt and brush grinding machines that provide the final finish on furniture components such as cabinets, beds, tables and kitchens.

In close collaboration with users and manufacturers, we have developed the right feed belt for every application, whether it be for a small workshop or the furniture industry. Our feed belts are used in grinding and brushing machines.

Thanks to the low manufacturing tolerances in the production of our BestBelt feed belts, you can always achieve excellent sanding results. Our feed belts are available in different splice types: finger joint, V-splice and straight joint.

| Width (in mm) max. | Length (mm), from | Length (mm) to |

| 1380 | 2000 | 15500 |

| 1600 | 2750 | 15500 |

| 2800 | 4100 | on request |

| Width (in mm) max. | Length (mm), from | Length (mm) to |

| 2.450 | 2.300 | 16.000 |

| Width (in mm) max. | Length (mm), from | Length (mm) to |

| 2.400 | 2.300 | 16.000 |

| Ø 2.0 – 9.5 | 2.000 | 15.500 |

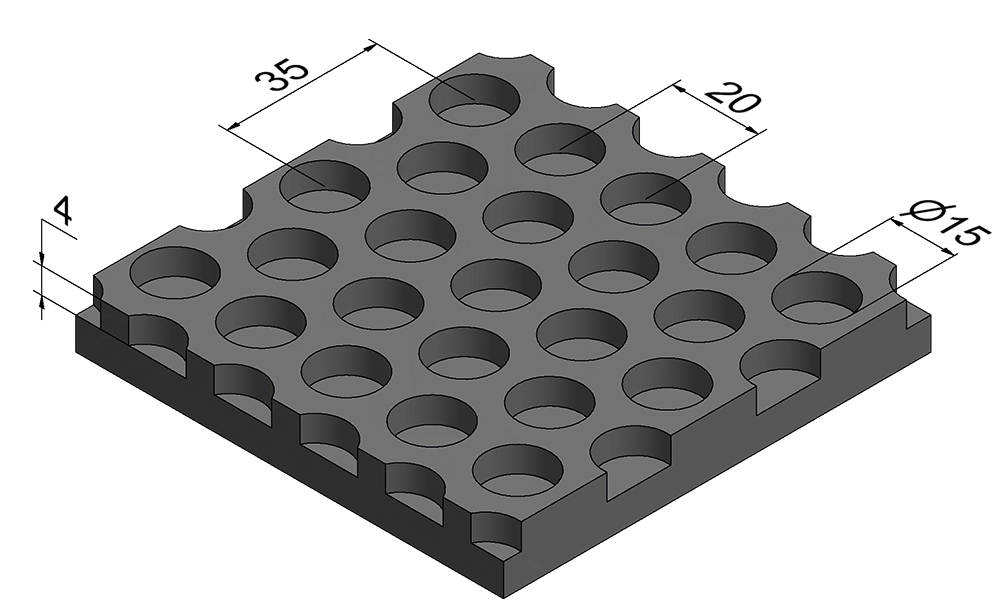

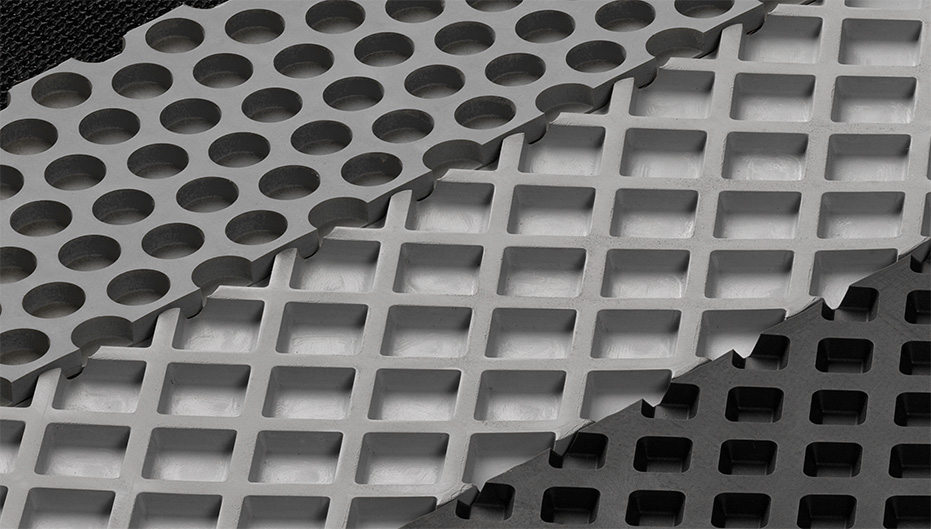

Round hole

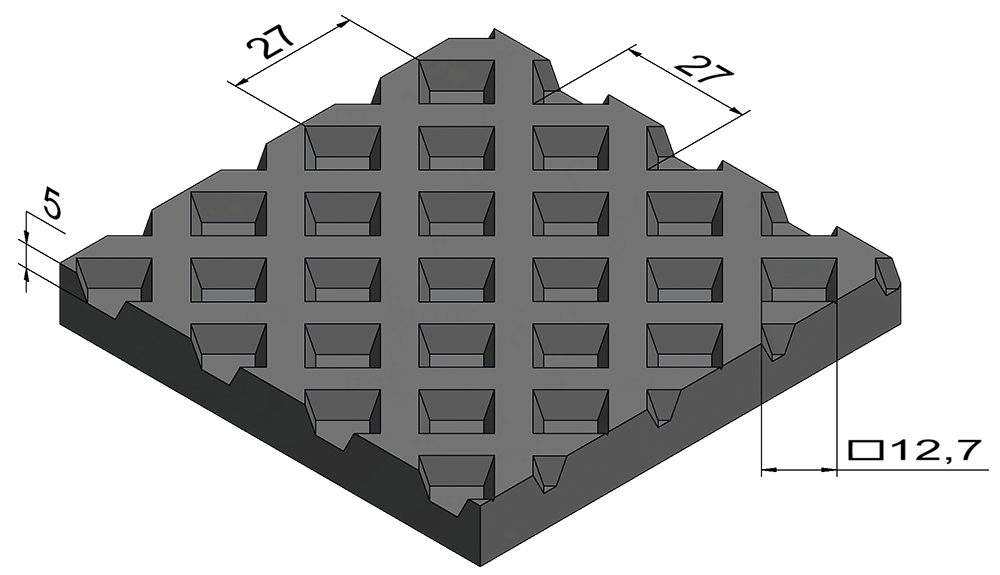

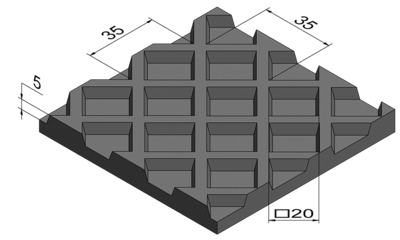

1/2 '' Diamond

1″ Diamond

Smooth

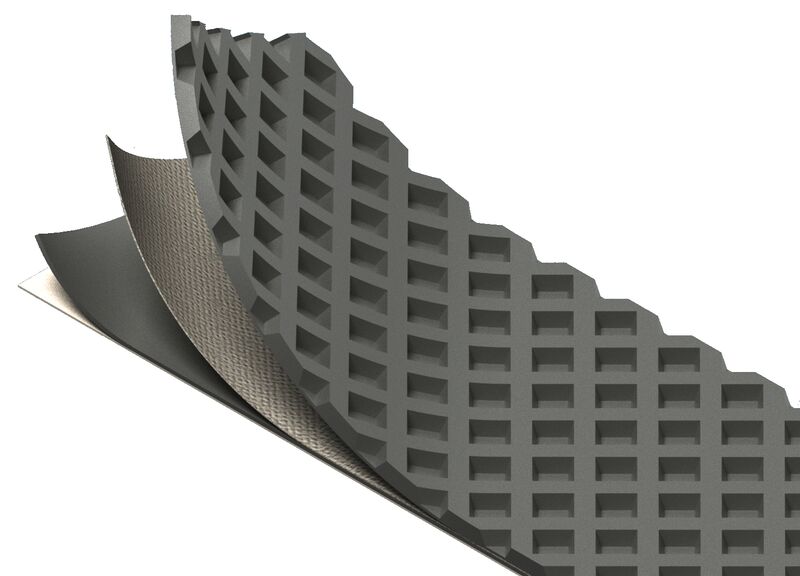

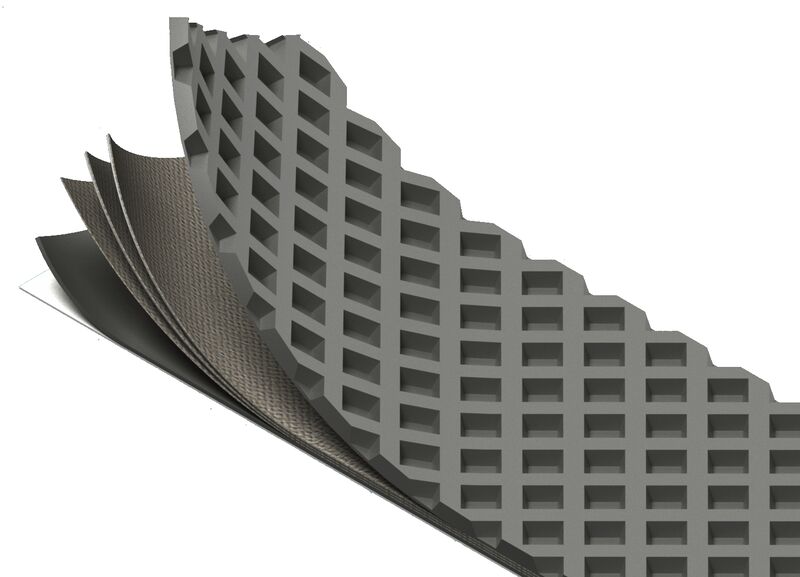

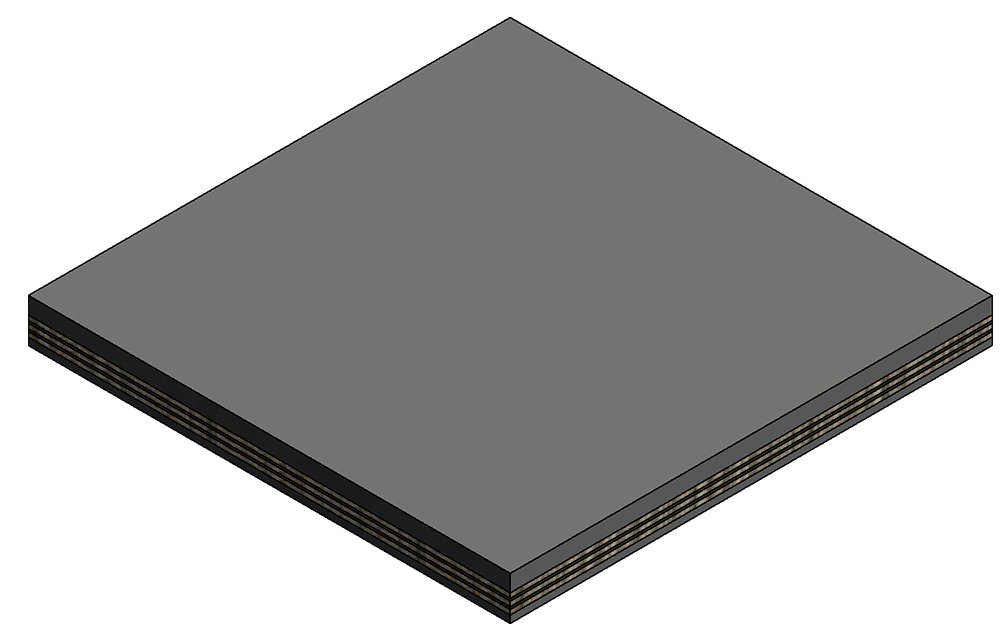

Our conveyor belts consist of four elements: the cover with various profile variants, the tension member, the intermediate rubber and the sliding layer.

We offer our cover plates with various surface structures – they are specially adapted to the material and the type of processing you use. Our highly abrasion-resistant sliding layers for wet and dry grinding and low-stretch tension member fabrics combined with intermediate rubber are characterized by consistent product quality. Innovative joining techniques also offer maximum durability.

Cover plate

Intermediate rubber

Tension plies

Sliding layer